Bar Solder & Pot Maintenance

About Bar Solder

Solder can be made into many different physical forms including wire, bar, and powder. Solder bar is simply solder in bar form. Florida CirTech uses a casting process in a nitrogen atmosphere to produce bar solder with a very low oxide content.

SN100CL Lead-Free HASL

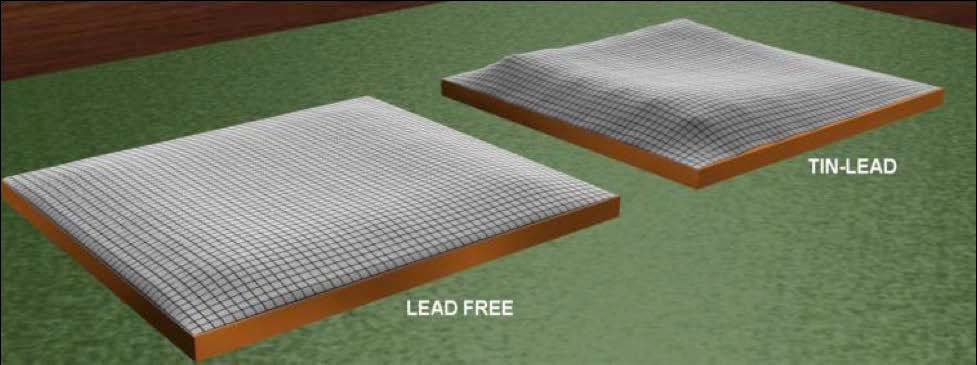

The transition to lead free solder has forced many companies to evaluate their PCB final finish. One of the more popular finishes is Hot Air Surface Leveling otherwise known as HASL. Florida CirTech, in collaboration with Nihon Superior, has established a viable lead free HASL process utilizing the SN100CL lead free alloy. SN100CL Lead-Free HASL process offers superior solderability to other competitive final finishes.

Many in the board industry are concerned about switching from HASL to a less forgiving final finish as they transition to lead-free. Our process will ease these concerns.

Nitro-Flo Plus Leaded Bar

Florida CirTech\’s Nitro-Flo Plus bar solder is cast under an inert atmosphere, which produces an ultra-low oxide bar. Florida CirTech pioneered an automated system that casts every bar without the use of manual labor to eliminate contaminates. This proprietary manufacturing process yields a bar that will produce the lowest dross levels during soldering operations.

Nitro-Flo Plus is made to offer the purest solder sold to the market. Florida CirTech provides complete analysis services to ensure each customer’s soldering operations are within specifications.

Solder Pot Maintenance

Florida Cirtech provides various lab testing & services including solder pot analysis. Contact us today to schedule your analysis. In addition, we have developed several maintenance products that will keep everything in spec.

AO-1000 Anti-Oxidant

AO1000 is a germanium (Ge) concentrate. When added to SN100CL HASL solder, AO1000 eliminates tarnish and will maintain a bright, shiny solder surface.

• Lead free

• Less dross formation

• Better wetting

• Smooth, bright fillets

• Lower solder use

• Less mess than oil covers

Ni-10 Additive

Nickel 10 Additive is intended as an additive to increase the nickel content of SN100CL lead-free solder. SN100CLe should be used for regular additions to maintain the level of the solder pot.

• Nominal nickel concentration (10% by weight)

• Calculation:

(0.05% – Current Ni content)

x (Total SN100CL weight in lbs)

x 0.10

= Weight of Nickel 10 Additive required (lbs)

Consult our Team

Florida CirTech offers a wide variety of chemical technology solutions, across multiple industries. We are more than happy to work with customers to provide custom chemical solutions for whatever needs you may have. Contact us to discuss your order or any questions you may have!